Ordinarily, the micropile shaft is possibly pushed or drilled into situation. Some kind of bearing element must be made if the desired pile capability cannot be attained in close bearing and side friction alongside the pipe. This might entail drilling a rock socket, filling it with grout, and putting in an entire size, high-energy threaded bar When the suggestion is roofed in rock.

b) Micropiles might be customised and utilized for tricky terrains and purposes. The apps can possibly be in the form of latest hundreds remaining additional to an present structure.

The bearing stratum is logged in the course of installation drilling to be sure that bearing ability is satisfactory.

On account of their flexibility, micropiles are commonly used in foundation maintenance, ground stabilization, and retrofitting initiatives. They may be excellent in situations in which soil is free, gentle, or unstable—specifically in urban or densely created spots exactly where space is limited.

They could be set up even though bypassing current utilities, reducing the necessity for high priced utility re-routing.

The surface area space of contact amongst the bottom and the concrete under the casing is named bearing stratum.

The adaptability of micropiles makes them a fantastic option for difficult foundation mend jobs.

makes use of air or drinking water as a flushing medium for eliminating the drilled elements with the drill hole. The air jet บริการตอกเสาเข็ม ราคา or drinking water pumped through the drilling technique exit in the drill little bit stop flushing out the cuttings.

This method is analogous to Type C . In this method primary grout บริษัทรับตอกเสาเข็ม is done stressed and right after hardening secondary grout is completed by means of set up sleeve ports. Packers are furnished for a number of injections.

When these types of disorders exist, experienced and grouted micropiles present a cost-effective, deep foundation possibility effective at penetrating obstructions linked amongst qualified bedrock.

Next removing with the drilling rod and instruments, reinforcement bars—ordinarily corrosion-resistant metal bars—are up coming put in the boreholes. Upcoming, grouting is completed sequentially under pressure as the casing is step by step eliminated.

The micropiles will penetrate any obstructions which will typically lead to premature refusal While Placing in mistreatment usual spile procedures.

Content Variety: Micropiles are created with higher-toughness steel casings or rebar to face up to axial and lateral masses.

whose diameter ranges from fifty mm to three hundred mm. The drilled / bored holes are grouted with cement immediately after inserting the reinforcement bars. Micropiles รับตอกเสาเข็มไมโครไพล์ นนทบุรี can withstand axial loads, lateral loads, or both and will negotiate hundreds ranging amongst 3T to 300T and a lot more.

Tia Carrere Then & Now!

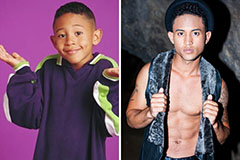

Tia Carrere Then & Now! Tahj Mowry Then & Now!

Tahj Mowry Then & Now! Michelle Trachtenberg Then & Now!

Michelle Trachtenberg Then & Now! Mason Reese Then & Now!

Mason Reese Then & Now! Lynda Carter Then & Now!

Lynda Carter Then & Now!